Product name | ppgi | ppgl |

Grade | DX51D+Z | DX51D+AZ |

Coating | Z50-Z140g/m2 (customize) | AZ30-AZ160g/m2 (customize) |

zinc | zinc and aluminum, silicone | |

Application | indoor applications where there is minimal exposure to harsh weather conditions. | suitable for outdoor applications where it will be exposed to harsh weather conditions |

Standard | JIS G3302/3312, ASTM A653 | |

Base Material | cold rolled steel | |

Thickness | 0.12mm-2.0mm generally (customized) | |

Width | 600-1500mm (1250mm,1000mm,1240mm,1500mm,914mm,750mm etc customized) | |

Paint Type | PVDF/High durability polyester(HDP)/Silicon modified polyester(SMP)/Polyester(PE)(as customer require) | |

Paint Top | 10-35 microns | |

Paint Back | 5-20 microns | |

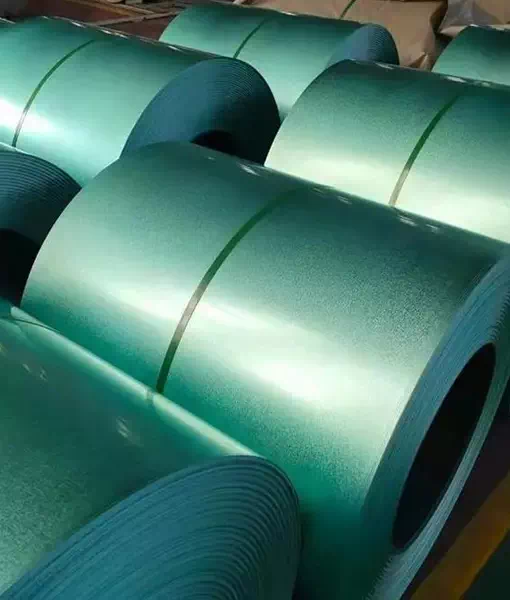

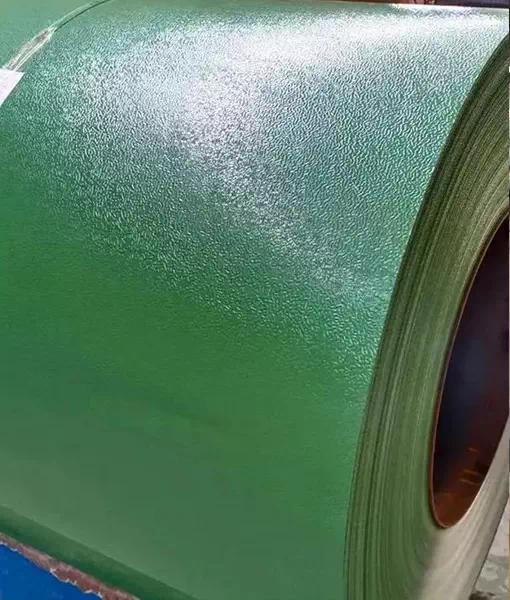

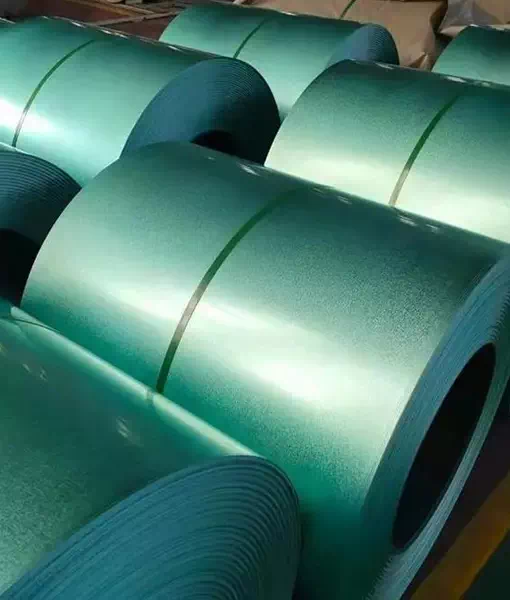

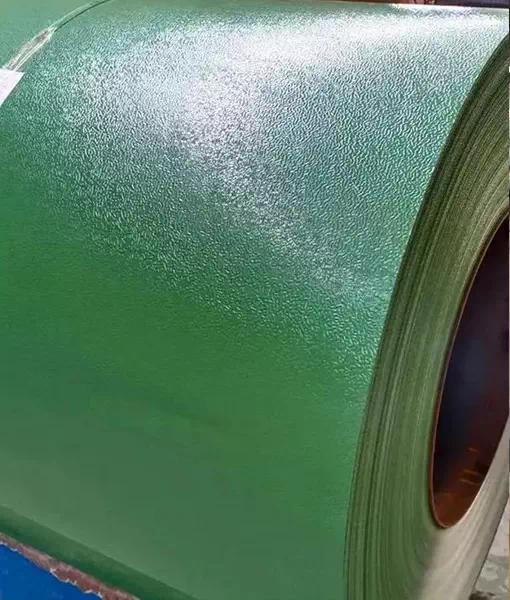

Surface Treatment | matt wrinkle, pure color high gloss, patterned (please send us color code if you are looking for color coated ppgi or ppgl) | |

Weight | PPGL weighs less than PPGI | |

ID | 508mm/610mm | |

Weight of coil | 3-8ton | |

Moq | welcome to chat with our sales person | |

Delivery Time | 5-25 days after payment | |

Supply Ability | 20000 tons/month | |

Package | water-proof paper, moisture-proof film, iron sheet wrapped, steel belt fixed | |

Color-coated coils use hot-dip galvanized steel coils as the substrate, and the color-coated steel coils are first surface pretreated, then coated with one or more layers of liquid coatings by roller coating, and finally baked and cooled. Coatings used include polyester, silicon modified polyester, high durability, corrosion resistance and formability. PPGI is pre-painted galvanised iron, also known as pre-coated steel, coil coated steel, color coated steel etc., typically with a hot dip zinc coated steel substrate. Galvanized steel, PPGI, is coated completely with zinc. While Galvalume steel, PPGL is coated with aluminum, zinc, and a small amount of silicone.

The spray paint structure generally consists of five parts. 1) Topcoat: block the sun and prevent ultraviolet rays from damaging the coating; when the topcoat reaches the specified thickness, it can form a dense shielding film to reduce water permeability and oxygen permeability 2) Primer: It is conducive to strengthening the adhesion to the primer, making the paint film difficult to detach after water penetration, and improving corrosion resistance, because the primer contains corrosion-inhibiting pigments such as chromate, which can passivate the anode and improve corrosion resistance. 3) Coating: Generally, it is galvanized or galvalume, which has a great influence on the service life of the product. The thicker the coating, the better the corrosion resistance. 4) Substrate: Generally, it is a cold-rolled sheet, and different strengths determine the mechanical properties of the color-coated sheet. 5) Back paint: the function is to prevent the steel plate from corroding from the inside, generally a two-layer structure (2/1M or 2/2, primer + back paint). If bonding is required on the back side, a single layer construction is recommended.

What kind of spray paint is used has an impact on the performance of ppgi and ppgl, basically there are 4 types. --Polyester (PE) has good adhesion, rich colors, a wide range in formability and outdoor durability, moderate chemical resistance, and low cost. --Silicon-modified polyester (SMP), the coating film has good hardness, wear resistance and heat resistance, as well as good external durability, chalking resistance and gloss retention, general flexibility, and medium cost. --High-durability polyester (HDP), with excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good film adhesion, rich colors, and excellent cost performance. --Polyvinylidene fluoride (PVDF), has excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance and good formability, dirt resistance, but limited color, cost high.

Sales hotline:

Scan and consult wechat customer service

Scan and consult wechat customer service