Item | Hot Dip Galvanized Steel Sheet |

Length | 1-12m or as required |

Width | 0.6m-3m or as required |

Thickness | 0.1mm-300mm or as required |

Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

Technique | Cold rolled |

Surface Treatment | Clean, blasting and painting according to customer requirement |

Thickness tolerance | ±0.15mm |

Material | Q345,Q345A,Q345B,Q345C,Q345D,Q345E,Q235B |

Coatings | Top Coats :5 micron primer + 20 micron colour Back Coat: 5 micron primer – 7 micron primer |

MOQ | 1tons.We also can accept sample order. |

Shipment time | Within 15-20 workdays after receiving deposit or L/C |

Export packing | Waterproof paper, and steel strip packed. |

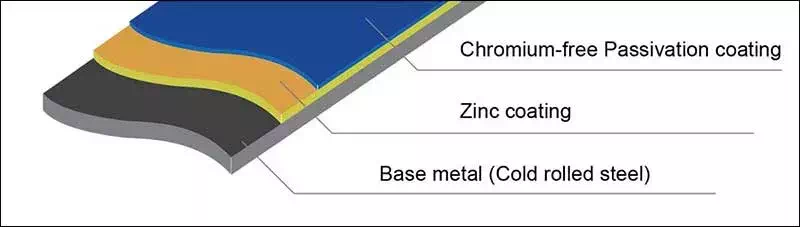

Hot dip galvanized steel plate is a kind of steel, belongs to galvanized steel, manufacturing process is to make steel and molten zinc reaction to produce an alloy. Hot dip galvanized steel plate (GI), a kind of steel, belongs to galvanized steel, also known as GI material.

Hot-dip galvanizing is the reaction of molten metal with an iron substrate to produce an alloy layer,

thereby combining the substrate and the plating layer. Hot-dip galvanizing is to pickle iron and steel parts first. In order to remove iron oxide on the surface of iron and steel parts, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed solution of ammonium chloride and zinc chloride.And then sent to the hot-dip plating bath. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

The manufacturing process of hot-dip galvanized steel plate is to immerse cleaned iron parts into zinc bath through the wetting effect of Flux, so that steel and molten zinc react to form an alloyed skin film.

Anti rust, anti corrosion, strong weather resistance. Corrosion resistance is very good, the general environmental corrosion prevention effect can reach 30~50 years.

Beautiful appearance and easy processing.

Reliable:The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more durable.

Strong toughness:The galvanized layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

Comprehensive protection:Every part of the plated piece can be galvanized,and is fully protected even in depressions,sharp corners,and hidden places.

Save time and energy:Galvanizing process is faster than other coating methods.

Sales hotline:

Scan and consult wechat customer service

Scan and consult wechat customer service