INVENTORY | ||

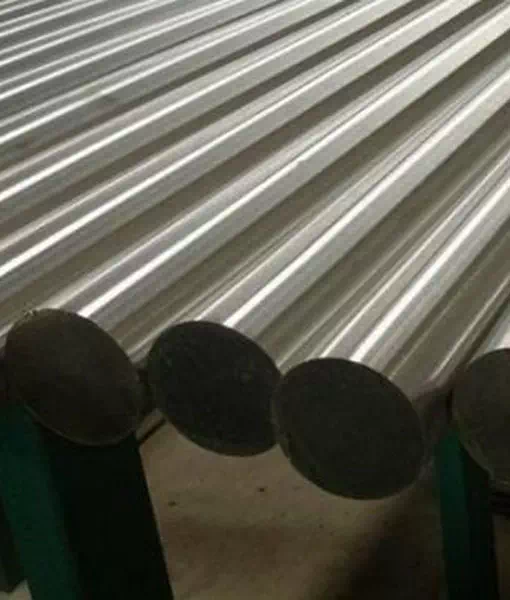

PRODUCT FORM | SIZE RANGE FROM | SIZE RANGE TO |

Alloy 625 pipe | 0.5 in | 8 in |

Alloy 625 coil | 0.25 mm | 3.18 mm |

Alloy 625 welding wire | 0.5 mm | 3.175 mm |

Alloy 625 sheet & plate | 0.25 mm | 76.2 mm |

Alloy 625 round bar | 12 mm | 260 mm |

Alloy 625 pipe fittings | 0.5 in | 8 in |

Alloy 625 filanges | 0.5 in | 8 in |

Jet engine exhaust systems

Engine thrust- reverser systems

Aircraft ducting systems

Turbine shroud rings

Bellows and expansion joints

Seawater components

Chemical process equipment

Alloy 625 is a nonmagnetic , corrosion - and oxidation-resistant, nickel-based alloy. Its outstanding strength and toughness in the temperature range cryogenic to 2000°F (1093°C) are derived primarily from the solid solution effects of the refractory metals, columbium and molybdenum, in a nickel-chromium matrix. The alloy has excellent fatigue strength and stress-corrosion cracking resistance to chloride ions. Some typical applications for alloy 625 have included heat shields, furnace hardware, gas turbine engine ducting, combustion liners and spray bars, chemical plant hardware, and special seawater applications.

CORROSION RESISTANCE

Alloy 625 has withstood many corrosive environments. In alkaline, salt water, fresh water, neutral salts, and in the air, almost no attack occurs. The nickel and chromium provide resistance to oxidizing environments. Nickel and molybdenum provide for resistance to no oxidizing atmospheres.

Pitting and crevice corrosion are prevented by molybdenum. Niobium stabilizes the alloy against sensitization during welding. Chloride stress-corrosion cracking resistance is excellent. The alloy resists scaling and oxidation at high temperatures.

Sales hotline:

Scan and consult wechat customer service

Scan and consult wechat customer service