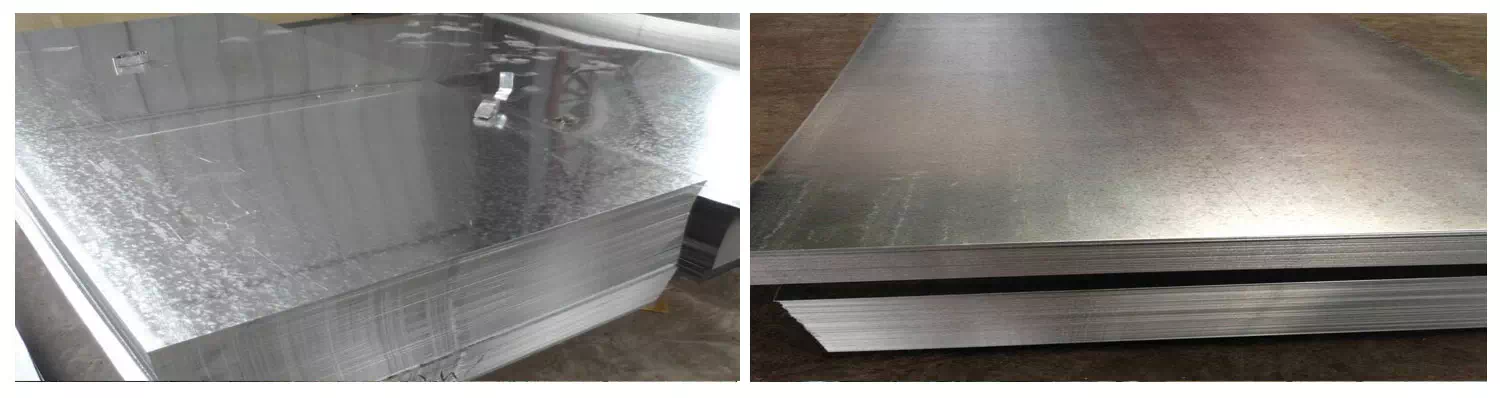

Galvanized steel plate is a new type of material formed by the composite of steel and zinc. This galvanized product perfectly combines the advantages of the two materials, so that the composite material has both the strength and plasticity of steel, but also has a corrosion resistant coating. Therefore, it has a wide range of applications in industrial fields such as construction, home appliances and automobiles.

In atmospheric environments, zinc is much more resistant to corrosion than steel. Normally, zinc is 25 times more resistant to corrosion than steel. This is why galvanized steel can maintain good performance in a variety of harsh environments.

Hot plating and electroplating are two main processes for galvanizing steel plates. Among them, hot-dip galvanizing is a method of directly immersing the treated strip steel into the molten zinc solution for galvanizing. The main steps of this method include uncoiling and welding, degreasing cleaning, annealing, air knife zinc layer control, alloying treatment, leveling and tension straightening, post-treatment, trimming and oiling.

First of all, the steel coil is uncoiled to provide the steel strip required for continuous operation, and the tail of the forward strip and the lead of the rear strip are welded to ensure the continuous production of the unit. Then, the strip surface is cleaned to remove rolling oil and iron powder in order to obtain good coating adhesion and surface quality. Next, recrystallization annealing is carried out on the rolled hard strip to obtain good mechanical properties of the product. Then, the coating thickness of the strip surface is controlled by spraying gas, usually air or pure nitrogen, to the strip surface after the zinc pan. Then, the galvanized strip steel is heated to obtain the zinc-iron alloy coating process. Then, the strip is rolled with small rolling force to eliminate the yield platform of low carbon steel, improve the performance of the strip, obtain the desired surface roughness of the strip, improve the shape of the strip plate, and obtain a good flatness. After leveling is tension straightening, tension straightening is to stretch the strip steel, the most important is to obtain a good plate shape. The strip is then subjected to passivation or other chemical surface treatments to obtain the corrosion resistance, lubrication, or other requirements desired by the user. Finally, the strip is edged as required to obtain the appropriate width accuracy. At the same time, the strip steel is oiled to obtain certain anti-rust and lubrication properties.

The main performance requirements of hot-dip galvanized products include two aspects: mechanical properties and coating properties. Mechanical properties mainly refer to the tensile test can confirm the performance of a single amount of products, such as yield strength, tensile strength, elongation, n value, r value, but also including baking hardening value and aging index. The properties of the coating mainly refer to the corrosion resistance of the coating and the adhesion properties of the coating. Corrosion resistance includes salt spray resistance and moisture resistance, and coating adhesion refers to the product's resistance to cracking, peeling, powder and other characteristics of the coating during processing.

Sales hotline:

Scan and consult wechat customer service

Scan and consult wechat customer service