310S alloy description

Alloy 310S is an austenitic chromium nickel stainless steel that posses good oxidation resistance and strength at high temperatures in continuous service up to 2000ºF (provided reducing sulfur gasses are not present). It is also used for intermittent service at temperatures up to 1900°F because it resists rescaling and has a low coefficient of expansion. This factor reduces the tendency of the steel to warp in heat service. Alloy 310S is similar to alloy 310 except for lower carbon content to minimize carbide precipitation during welding.

parameter

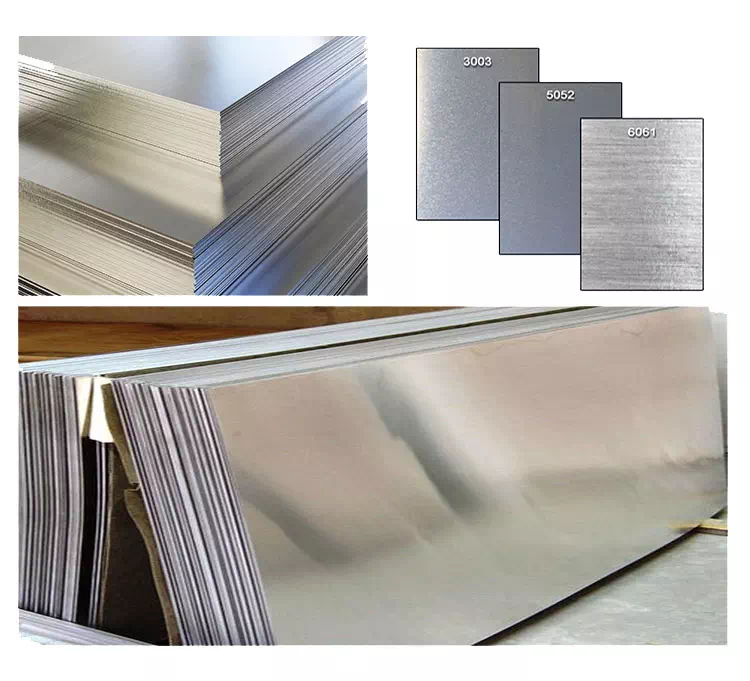

Grade | 1000,2000,3000,5000,6000,7000,8000 series |

| Tolerance | ±1% |

| Temper | T351-T851 |

| Type | Sheet |

| Width | 20-2000mm |

| Alloy Or Not | Is Alloy |

| Brand Name | Zhishang |

| Processing Service | Bending, Decoiling, Welding, Punching, Cutting |

| Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard. |

| Package | Standard Seaworthy Package |

310S ALLOY DESCRIPTION

Shaped, Flat, Square, Round, Fine, Plated and Bare Wire ASTM A167, AMS 5523

Alloy 310S is an austenitic chromium nickel stainless steel that posses good oxidation resistance and strength at high temperatures in continuous service up to 2000ºF (provided reducing sulfur gasses are not present). It is also used for intermittent service at temperatures up to 1900°F because it resists rescaling and has a low coefficient of expansion. This factor reduces the tendency of the steel to warp in heat service. Alloy 310S is similar to alloy 310 except for lower carbon content to minimize carbide precipitation during welding.

APPLICATIONS

Furnace parts

Heat Exchangers

Paper Mill Equipment

Exhaust Parts in Gas Turbines

Jet Engine Parts

Oil Refinery Equipment

CHEMISTRY TYPICAL

Carbon: 0.080 max

Manganese: 2.00 max

Silicon: 0.75 max

Chromium: 24.00- 26.00

Nickel: 19.00- 22.00

Molybdenum: 0.75 max

Phosphorus: 0.040 max

PHYSICAL PROPERTIES

Density, 0.29 lbs/in³ 9.01 g/cm³

Electrical Resistivity: microhm-in (microhm-cm): 68°F (20°C): 37.0 (94.0)

Specific Heat: BTU/lb/°F (kJ/kg•K): 32-212°F (0-100°C): 0.12 (0.50)

Thermal Conductivity: BTU/hr/ft²/ft/°F (W/m•K):

At 212°F (100°C): 8.0 (13.8)

At 932°F (500°C):10.8 (18.7)

Mean Coefficient of Thermal Expansion:in/in/°F (μm/m•K)

32-212°F (0-100°C): 8.0 x 10 (14.4)

32-600°F (0-315°C): 9.3 x 10 (16.7)

32-1000°F (0-538°C): 9.6 x 10 (17.3)

32-1200°F (0-649°C) : 9.7x 10 (17.5)

Modulus of Elasticity: KSI (MPa) 29.0 x 10³ (200 x 10³) in tension 11.2 x 10³ ( 78 x 10³) in torsion

Magnetic Permeability: H = 200 Oersteds: Annealed: < 1.02 max

Melting Range: °F (°C) 2550 – 2650 (1399 – 1454)

MECHANICAL PROPERTIES AT ROOM TEMPERATURE

PROPERTIES: ANNEALED

Ultimate Tensile Strength: 75 KSI min (515 MPA min)

Yield Strength (0.2% offset): 30 KSI min (205 MPA min)

Elongation: 40% min Hardness: Rb 95 max

Properties: Tempered 310S can be supplied in a various rolled tempered conditions.

Contact Ulbrich Technical Service for details.

ADDITIONAL PROPERTIES

CORROSION RESISTANCE

Properties Tempered Alloy 310S can be cold rolled to achieve the temper properties

required by specific customers and/or manufacturing requirements.

STANDARD WIRE FINISHES

Extra Clean: (XC) Extra clean is also referred to as “bright annealed” or “bright annealed and cold rolled”

Grease (round wire only): Drawn in a heavy grease produces an “Ultra bright” finish for

decorative applications Soap (round wire only):

Soap is used as a lubricant in the drawing process and is not removed. It acts as a lubricant during customer part forming operation. A soap finish is available in tempered products.

Plated: Many plating options are available.

FORMS

Continuous Coils

Cut to lengths

Precision cutting

Cold Forming Alloy 310S has a good ductility and can be rolled formed, stamped and drawn readily.

Heat Treatment Alloy 310S can only be hardened by cold working.

Online Message

Recommended Products

News Center

- The advantages of floor deck slabs 2025-08-18

- Modern Stainless Steel Railing Handrails for Steel Stairs — Engineered for Safety and Aesthetics 2025-08-01

- RAL color pre-coated steel coils lead the new trend of architectural aesthetics 2025-07-30

- Stainless Steel Industry Powers Global Innovation Amid Rising Demand and Green Transition 2025-07-29

- High-Strength S355JR / A106 Gr.B Carbon Steel Pipes | EN 10025-2 & ASTM A106 Standard 2025-07-28

- 347H Stainless Steel Plate Supplier | Heat-Resistant Austenitic Stainless Steel for Petrochemical & Power Industries 2025-07-25

- Hot Rolled S275JR Carbon Steel Coil | Structural-Grade Mild Steel for Industrial Use 2025-07-24

- 1050 Galvanized Steel Wire | High-Strength Zinc-Coated Wire for Industrial Use 2025-07-22

- S220GD Galvanized Steel Pipe | High-Strength Hot-Dip Zinc-Coated Structural Tube 2025-07-21

- Customized Steel Truss Deck Systems Gain Global Momentum in Modern Construction 2025-07-18

Сталь чжи сан

Zhishang steel co.Ltd,specializes in steel products,which mainly manufactures galvanized steel,galvalume steel,ppgl,ppgl and also can supply hot rolled steel, coldrolled steel,stainless,wire rod,h beam,steel pipe,etc.The company is committed to providing customers with high-quality and low-price steel products and strives tocreate value for custome···